Forestry & Harvesting

Technology for Forestry and Special Harvesting Machinery

Technology for the Forestry & Specialty Harvesting Industries

Forestry Machines We Power

Our technologies are used on various types of equipment and mobile machines

Brush Chippers

Debarkers

Delimbers

Log Skidders

Log Loaders

Harvesters

Stump Cutters

Tree Spades & Movers

Feller Bunchers

Mulchers

Yarders

Log Slitters

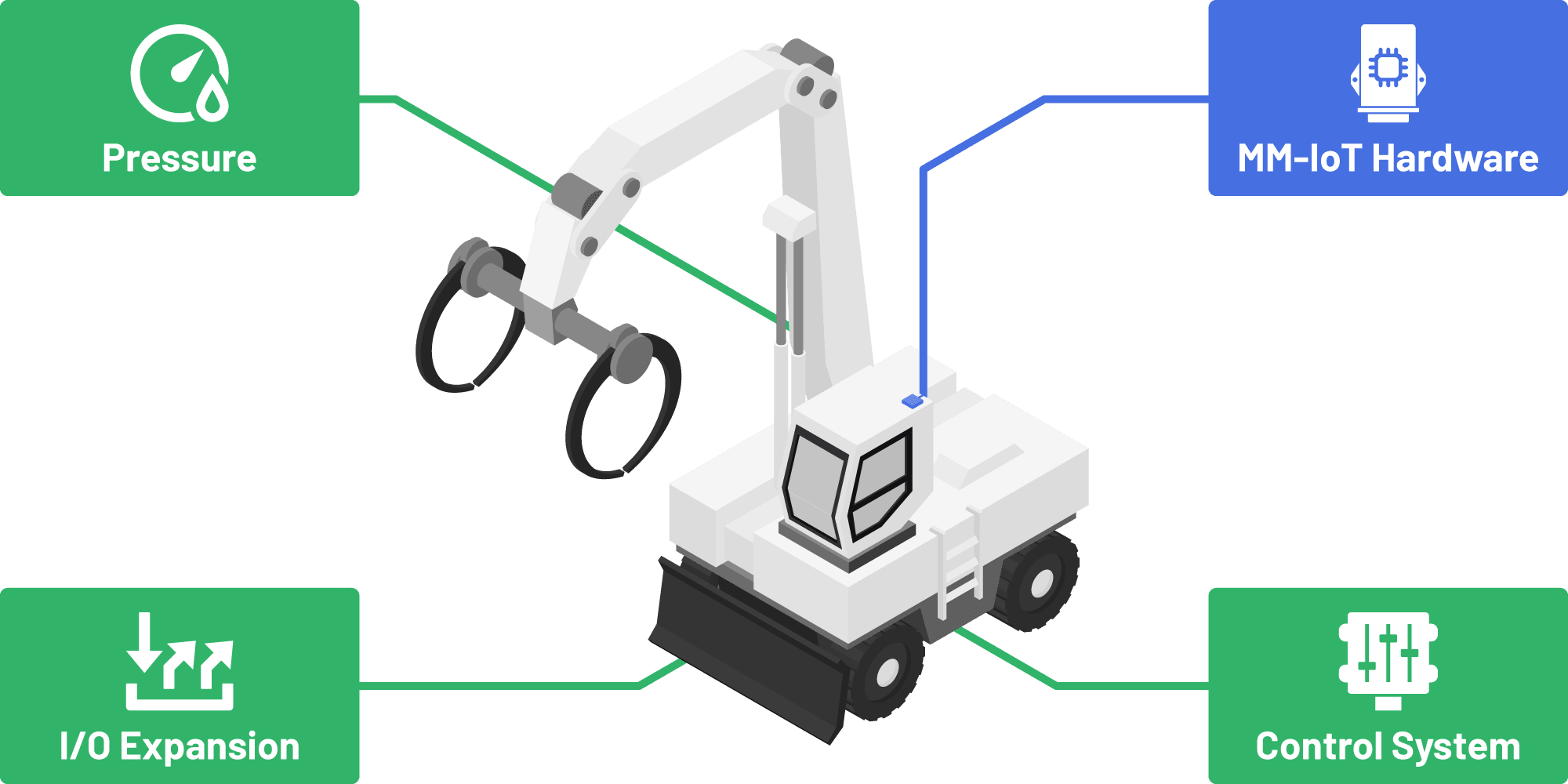

Enhance Your Vehicle Systems

Pressure Sensors

Get the most immediate pressure readings from your machines. Easy to add pressure sensors give you real-time values to help maximize the health of your machine during its lifecycle.

Explore More

MM-IoT Hardware

When you add edge computing hardware to your vehicles, the possibilities are virtually limitless. This enables real-time tracking, remote servicing, and cloud connectivity for future data acquisition.

Explore More

I/O Expansion

Easily expand your vehicle I/O connections. Our I/O Expansion modules are controller agnostic so you don't have to worry about drastic control system redesigns.

Explore More

Control System

Power your machines for any harsh working environment. Cur controllers are freely programmable with a unique architecture that allows you to easily expand I/O, CAN routing, and memory.

Explore More

Empowering Forestry Applications

STW technology is used to support the latest solutions for forestry vehicles and specialty harvesting equipment